For operation of HV AC and DC systems a EMC proven control system is required. The control system consists of an operating terminal (OT), a Windows® laptop (HMI) and a control rack, depending on the power of the HV system, with built in power components such as switches, compensation, filters, frequency converter etc.

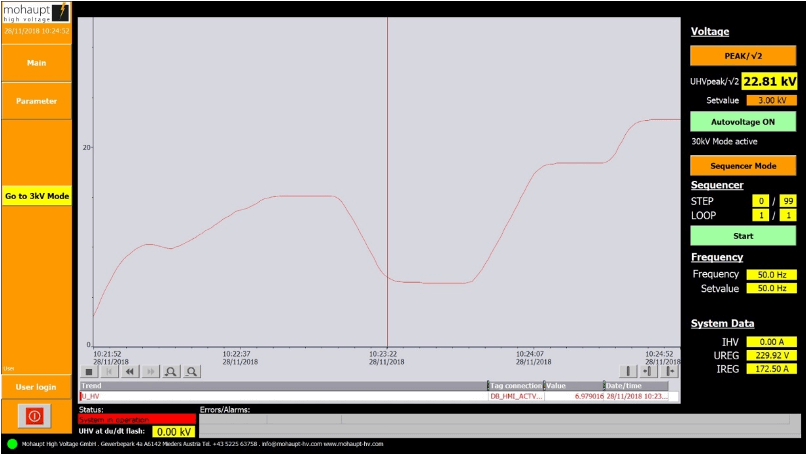

The control systems can be operated fully manually, semi-automatic or fully automatic. It is possible to use timer functions, as well as predefined individual test sequences.

- User friendly operation by reliable push buttons, no touch screen

- Easy to understand operating steps

- EMC prove concept by optical fibres

- Data recording and reporting acc. ISO9001

- Safety standards EC61508/EN62061/EN ISO13849/EN60204-1

- Complies with national standards, such as IEC, UL, CSA etc.

HV On/Off/Emergency Off

Voltage / Frequency / Inductance Up/Down/Fast/Automatic

Output voltage measurement (RMS/Peak/sqrt(2))

Automatic tuning

Timer function

Programmable sequences

Security functions connected by wire

Flash detection with hold function

Password protected limiter and calibration section

Automatic voltage control

Fiber optic connection to PLC

Data recording and reporting

In order to comply with the high EM stresses occurring during the operation of HV tests systems, the control system is especially developed to ensure a reliable operation throughout years. All data interconnections are realised by optical fibres, while safety relevant functions such as interlock (doors etc.) and emergency off are hard wired. The use of industrial proven components and careful grounding of those, as well as protecting all analog inputs ensures transient proven operation, even under high stresses, such as gas breakdowns.

Sets of spare parts are available in addition to guarantee 100% availability.